AKSIKOR – gruntoemalia (undercoat – enamel) for roof metal sheets

AKSIKOR combines surface paint with an undercoat. It is an acrylic, water-soluble, decor-protection, corrosion-proof paint of perfect adherence to surface characteristics. Based on the state of the art raw materials providing the highest quality.

Application

Application

AKSIKOR is designed for painting of:

– zinc-plated metal sheets and aluminium-zinc sheets

– roof gutters, fences and other zinc-plated or alu-zinc surfaces

– aluminium sheets

– copper surfaces

AKSIKOR is suitable for renovation of old coats (zinc-plated sheets painted with poly-vinyl paints or chloric-rubber paints)

AKSIKOR can be also used to paint steel elements (after previously covered with an undercoat), concrete, plasters if present in a civil engineering construction where maintaining the colour is required

AKSIKOR is part of the “Roofing sheet renovation system” which can be used for factory coated sheets

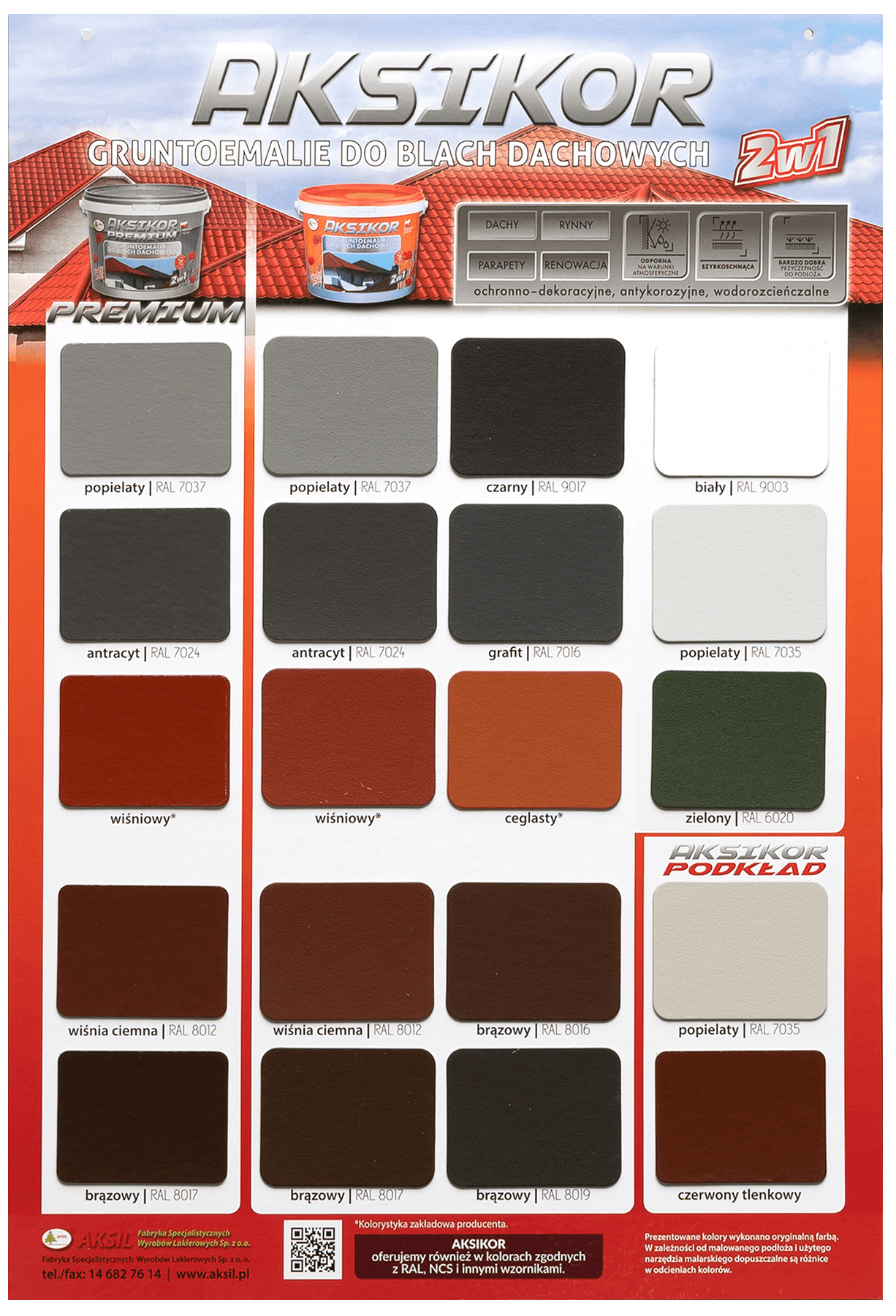

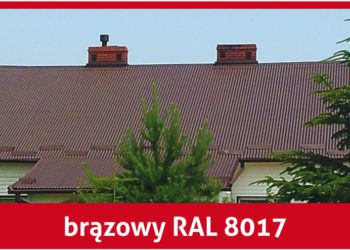

Colours

Colours

Characteristics

Characteristics

• efficiency in case of one layer of the paint: up to 10 m2 from 1 litre. It is recommended to apply at least two layers

• Eco product, water soluble, acrylic based

• The paint creates a fast-drying matt coats of very good adherence to surface characteristics

• The coat made of the paint is flexible and waterproof

• The paint is resistant to changing weather conditions

• Tested on metal sheet roofs – 5-year period – no degradation

• Very easy in use – smooth painting

• In contrary to solvent-based paint, does not generate harmful fumes and unpleasant odour and is safe for the user

Expert advice

Expert advice

Preparation of the surface with signs of corrosion:

The surfaces to be painted should be washed (preferably with a pressure washer) with water and detergent or Emulsol RN-1, then rinsed and dried. If there are traces of corrosion, the metal sheet should be mechanically of corrosion to clean metal. In order to provide additional protection against corrosion, paint the cleaned areas with AKSIKOR PRIMER anticorrosive primer. Apply AKSIKOR on AKSIKOR PRIMER after 24 hours.

Preparation for renovation of old coatings:

In case of renovation of old surfaces, remove old, veneering coat with the use of agents for removal of paints or a brush.

Smooth, shiny surfaces should be matted with sandpaper before painting. The surfaces to be painted should be washed (preferably with a pressure washer) with water and detergent or Emulsol RN-1, then rinsed and dried.

Check again for peeling of the old coating after washing and drying.

Warning: AKSIKOR paint painted on old, flaky paint will not improve its adhesion to the surface and will not stop the flaking process.

Preparation of galvanized steel sheet:

New galvanized surfaces can be painted after air exposure after approx. 1 year. Remove zinc corrosion products (white coating) with nylon brushes or non-woven fabric with abrasive introduced, soaked in 5% ammonia solution. The prepared surface should be washed (preferably with a pressure washer) with water with detergent or Emulsol RN-1, then rinse and dry.

Preparation of coated sheets:

The “Roofing sheet renovation system” should be used: AKSIKOR PRIMER + AKSIKOR.

The surfaces to be painted should be washed (preferably with a pressure washer) with water with detergent or Emulsol RN-1, then rinsed and dried.

AKSIKOR PRIMER should be applied in a commercial form in places where corrosion occurred (after its mechanical removal), apply the diluted foundation to the remaining surface. For dilution, use a thinner for chlorinated rubber products and styrenated. Apply AKSIKOR on AKSIKOR PRIMER after 24 hours.

Proper preparation of the surface before painting is important for obtaining full coating properties.

Painting:

Mix the paint in the packaging before use.

AKSIKOR should be applied with a brush, roller or spray. It is recommended to apply 2-3 layers. Apply the next layer after about 1 hour.

Note: When painting an intense dark surface with AKSIKOR in a light color, it may be necessary to apply 3 layers of paint.

Recommended parameters for hydrodynamic spraying:

– nozzle diameter 0.013-0.019 inch e.g. nozzle 513

– spray pressure approx. 175-200 bar

– spray angle 20 – 50 degrees

We recommend Wagner, WIVA and Kremlin pistols for spraying.

Painting works should be carried out at air and surface temperature between + 10 °C and + 30°C and relative humidity of air up to 80%. Painting works should be carried out in appropriate atmospheric conditions (no fog, rain or snow).

Tools to be cleaned with water.

Download

Download

(+14) 682 76 14

(+14) 682 76 14 aksil@aksil.pl

aksil@aksil.pl